Austenitic Stainless Steel Pipe/Tube

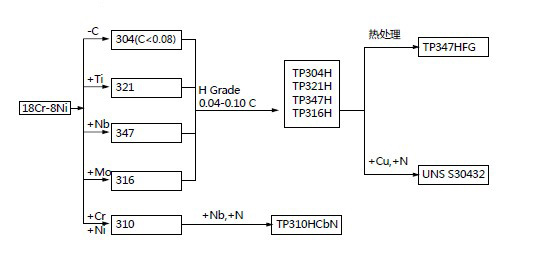

Austenitic stainless steel has austenite as its primary phase at both elevated and room temperature. A stable austenite structured steel contains about 18% Cr, 8% ~ 10% Ni and about 0.1% C. Chrome-nickel austenitic stainless steel including the most familiar stainless steel 18Cr-8Ni (TP304) and the series of high Cr-Ni steel developed by increase Cr, Ni contents and add Mo, Cu, Si, Nb, Ti and other elements. Austenitic stainless steel is characterized by non-magnetic, high plasticity and ductility but lower strength. It can be only strengthened via cold working (by adding S, Ca, Se, Te and etc, austenitic stainless steel can have excellent machinability).

Grades:304/L/H/LN, 316/L/H/LN/Ti/LMod, 310S/H, 317/L, 321/H, 347H/HFG

Specifications:

ASTM A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A790 Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASME SA213 Seamless Ferrite and Austenitic Alloy Steel Pipe for Boiler, Superheater and Heat Exchanger

ASME SA249 Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

ASME SA789 Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

GB/T14976-2002 Stainless steel seamless tubes for fluid transport

GB/T12771-2008 Stainless steel welded tubes for fluid transport

......

Features:

1.Excellent corrosion resistance

2.Good for cold working or hot working

3.High plasticity and ductility

4.Optimum general performance

5.A wide range of applications

Development diagram of common grades of austenitic stainless steel

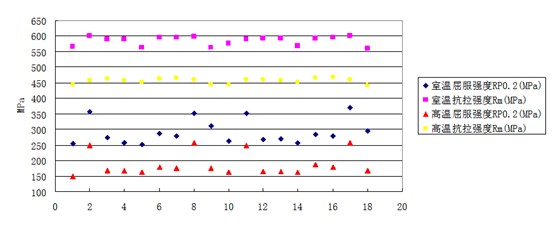

Strength Graph of Jiuli 316LMod at room and elevated temperature