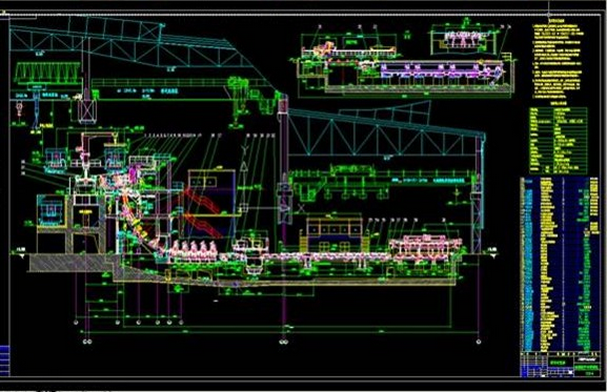

Technical Specification of Continuous Caster

|

Description

|

Parameter

|

|

Machine type

|

whole arc continuous caster

|

|

Arc radius

|

4.5-16.5m

continuously straightening

|

|

Strands

|

1-10

(depend on the continuous casting process)

|

|

Billet section

|

100X100mm-240X240mm,

Φ110mm-Φ330mm,

rectangular with any size

|

|

Length of billet cut-to-length

|

3-12m

|

|

Steel type

|

carbon steel, low alloy steel, high quality carbon steel, high alloy steel, stainless steel, bearing steel etc.

|

|

Strand distance

|

1200-1500mm

(depend on the continuous casting process)

|

|

Casting speed

|

0.5-3.6 m/min

(depend on the continuous casting process)

|

|

Dummy bar

|

rigid, flexible

|

|

Cooling type

|

whole water cooling,

air and water atomization cooling

|

|

Oscillation type

|

mechanical oscillation (semi board spring, whole board spring), hydraulic oscillation, sinusoidal oscillation, non-sinusoidal oscillation

|

|

Billet cut-to-length type

|

infrared camera+torch cutting machine

|

|

Straightening type

|

whole water cooling continuously straightening machine

|

|

Cutting type

|

pneumatic synchro fastening, pneumatic return motorless automatic torch cutting machine, double transmission automatic torch cutting machine

|

|

Roller bed

|

whole water cooling transporting roller bed

|